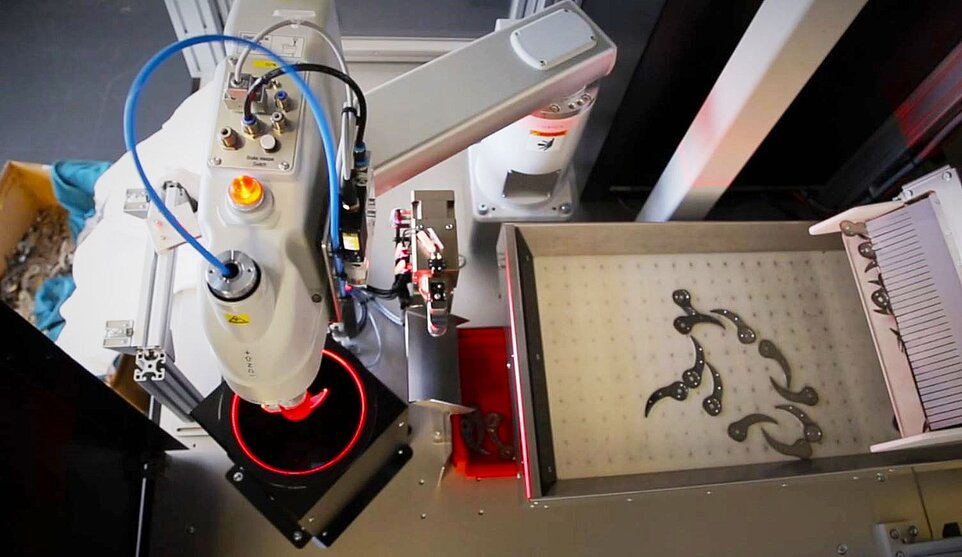

Easy separation, sorting and inspecting

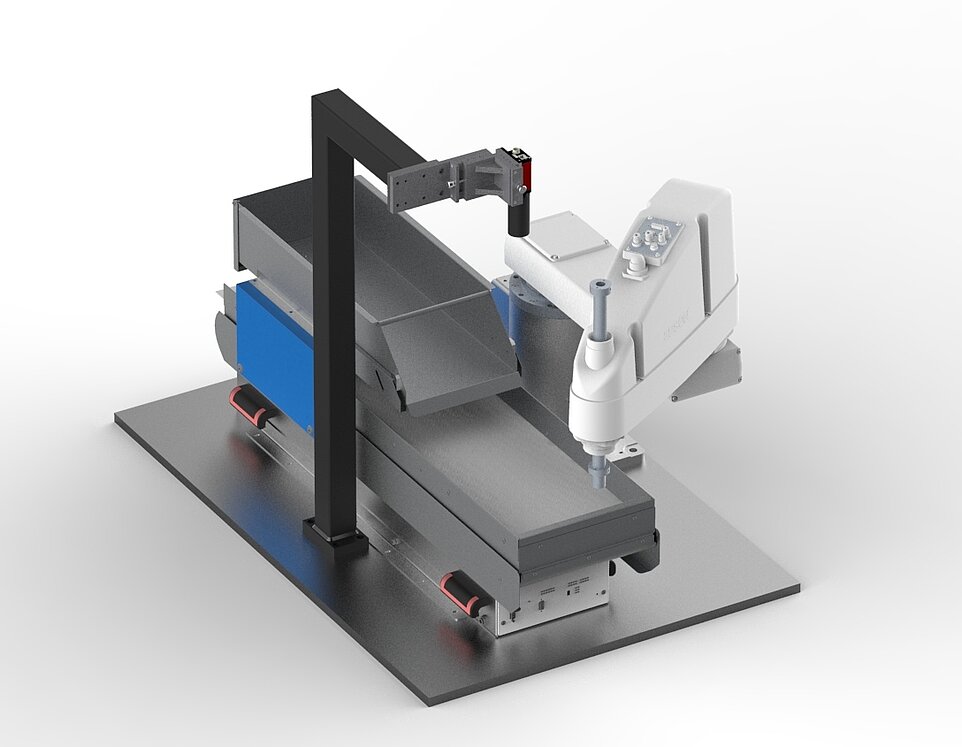

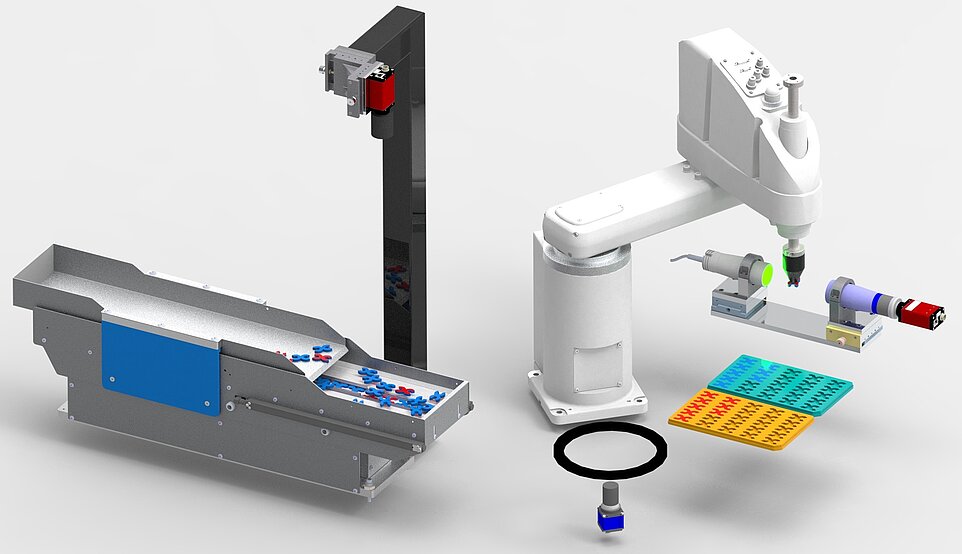

You’ve got bulk material – we’ve got the solution! The universal parts conveyance consists of only three components: vision system, robot and conveyor. The slim design saves space, development time and costs and convinces by its flexibility and reliability. Selecting an appropriate conveyor and robot type allows for processing part sizes from smallest watch components all the way to large medical implants. The robot coordinates machine vision, handling and feed. The robot’s operator interface provides the opportunity to autonomously control and coordinate the entire system. Costly PLC controls are thus unnecessary. Moreover, the system meets the pharma industry’s high requirements (such as FDA – Directive 21 CFR Part 11).

Customer benefits

- separation, sorting and inspecting at a single work step at minimum space requirements

- minimal number of components - compact system – budget-friendly solution

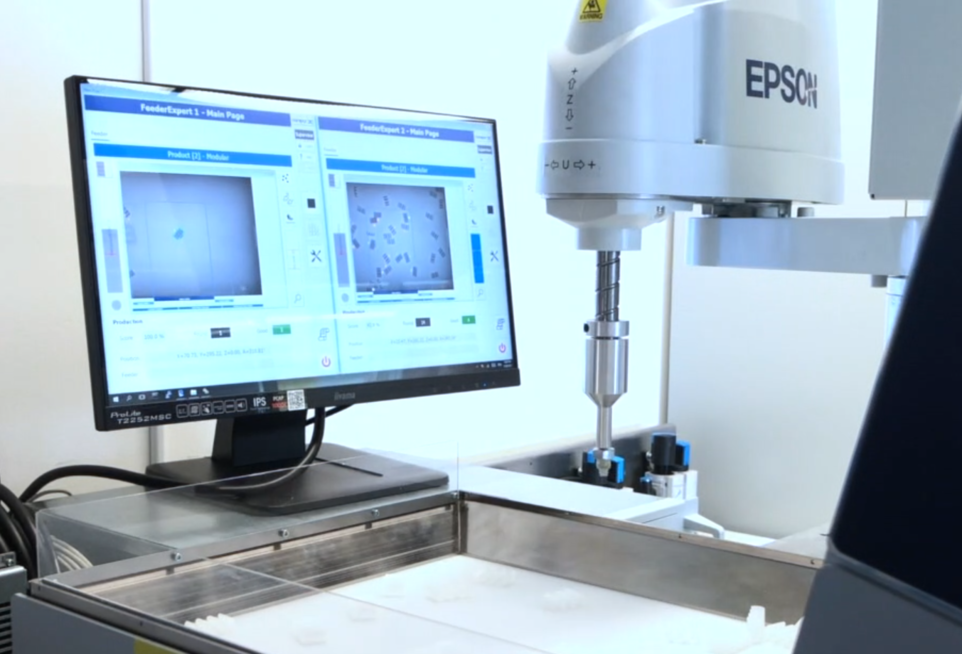

- all it takes to control and operate the system is a standard computer monitor and key-board/mouse

- resilient and reliable thanks to the standard components deployed

- full integration with fully automatic production. Input: unsorted/untested bulk material - output: sorted and palletized products, optional report included

- plant communication via all common inter-faces

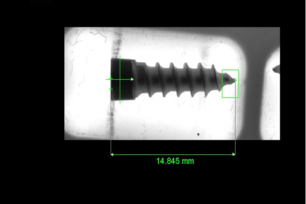

- graphical measured data presentation

Flexibility: the operator interface allows for teaching new products or modifying existent products.

Reliability: the individual components are tried-and-tested standard components frequently used.

Scalable system: selecting the appropriate conveyor and robot type facilitates the handling of part sizes ranging from 5 x 5 mm to 150 x 150mm. The modular system allows for deploying SCARA robots that feature a wide operating range, six-axle robots, PC-based multiple camera systems on or Cognex In-Sight for high-speed applications

High compatibility: the VISIONexpert® software provides all customary interfaces such as Ethernet, fieldbus systems (e.g. Profibus), RS 232 or digital I/Os for plant integration.

Easy to use: monitor and keyboard serve to display and control machine vision, reload jobs, issue/adapt new jobs or calibrate the system. With each new job, new products can be taught without having to modify or adapt the communication between individual system components.

Tamper-proof: various user levels serve to define authorizations, any subsequent modification will be logged for tracking. The system thus meets the pharma industry’s high requirements and is 21 CFR Part 11-compliant.

Reduction of system components: The robot acts as master. It coordinates the interaction between machine vision, handling and feeding. The vision system’s user interface facilitates the entire system’s autonomous control and coordination. PLCs or industrial computers can thus be spared.

System components

- Vision system VISIONexpert® on industrial PC

- Cognex In-Sight with optional display and control unit

- Handling system: e.g. Epson SCARA G1

- Feeding system: AnyFeeder made by Flexfactory in various sizes

Options

- Also available as autonomous inspection system

- Data base connectivity for statistics

- Validation support