From simple height profile measurements to high-precision dimensional checks of surface elevations with measurement accuracy in the micrometer range

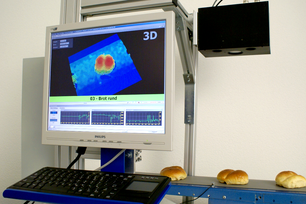

Measuring objects in 3D has several advantages in many applications. Additional depth information can be important for product identification, quality assurance or robot control. In volume measurement, they are practically indispensable. In practice, it is important to have robust results in different environmental conditions, surface qualities and colours of the products. Different methods help to achieve robust results. 3D measurement is used to inspect more complex parts made of a wide range of materials. Compar AG has numerous measurement libraries for 2D / 3D measurement technology as a measurement module of the holistic image processing software VISIONexpert®. Based on the customer's requirements, the appropriate algorithms for the solution are determined, tested and finally applied.

Perfect 3D measurement guaranteed

Thanks to various robust methods such as laser triangulation, stereo vision and interferometry.

Fastest processing times

3D standard solutions which are used in production lines as 100% online inspection systems.

Degrees of freedom and flexibility

Multi-camera solutions, robust 3D measurements from a combination of different processes and methods, use of different 3D manufacturer libraries.