Task

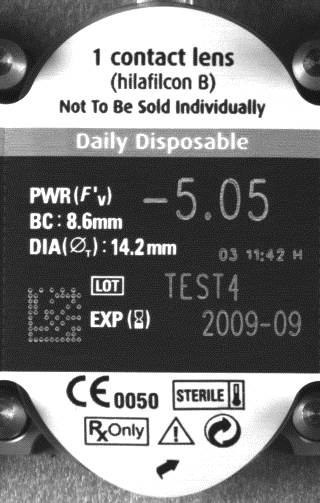

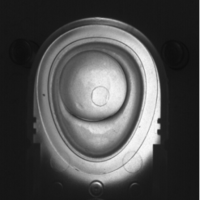

The production of contact lenses involves numerous manufacturing steps. In order to meet the high quality standards for contact lenses, there are many subtasks that we tackle on behalf of our customers. For instance, after injection moulding of plastics, checking for the presence of the casting mould and the lens, as well as detecting overmoulding. Another task is checking that the lens is present in the blister pack and detecting whether there are any drops of water or other foreign particles on the edges of the seal of the blister pack. During a subsequent step, blister packs with foils are checked. In the process, the foil position as well as the correctness and quality of the labelling is checked. Furthermore, the 2D data matrix code must be checked with respect to legibility.

Customer Benefit

Bad parts are sorted out and not refined further unnecessarily. Indirect process optimisations using the insight gained from an optical inspection. Important contribution to assure the quality of the end product.

Goods and Services Provided by Compar AG

Implementation and complete realisation of the optical inspection systems, including installation and commissioning with subsequent training. Ongoing support for the training of new products and periodic maintenance tasks.

Products Used

VISIONexpert® with numerous image acquisition stations, which are equipped with high-resolution cameras.