Fully Autonomous End of Line X-Ray Inspection

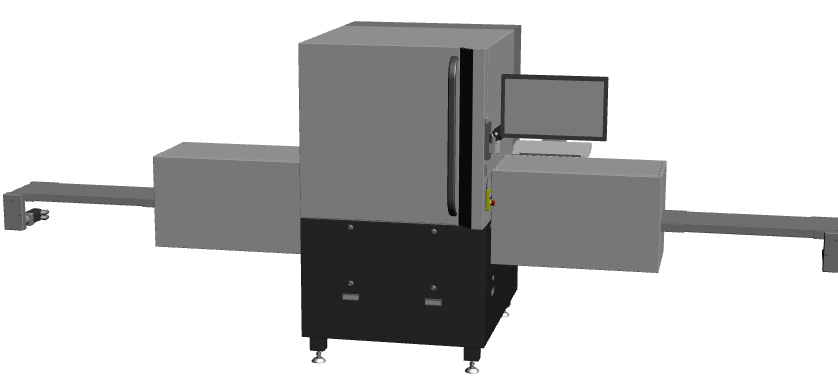

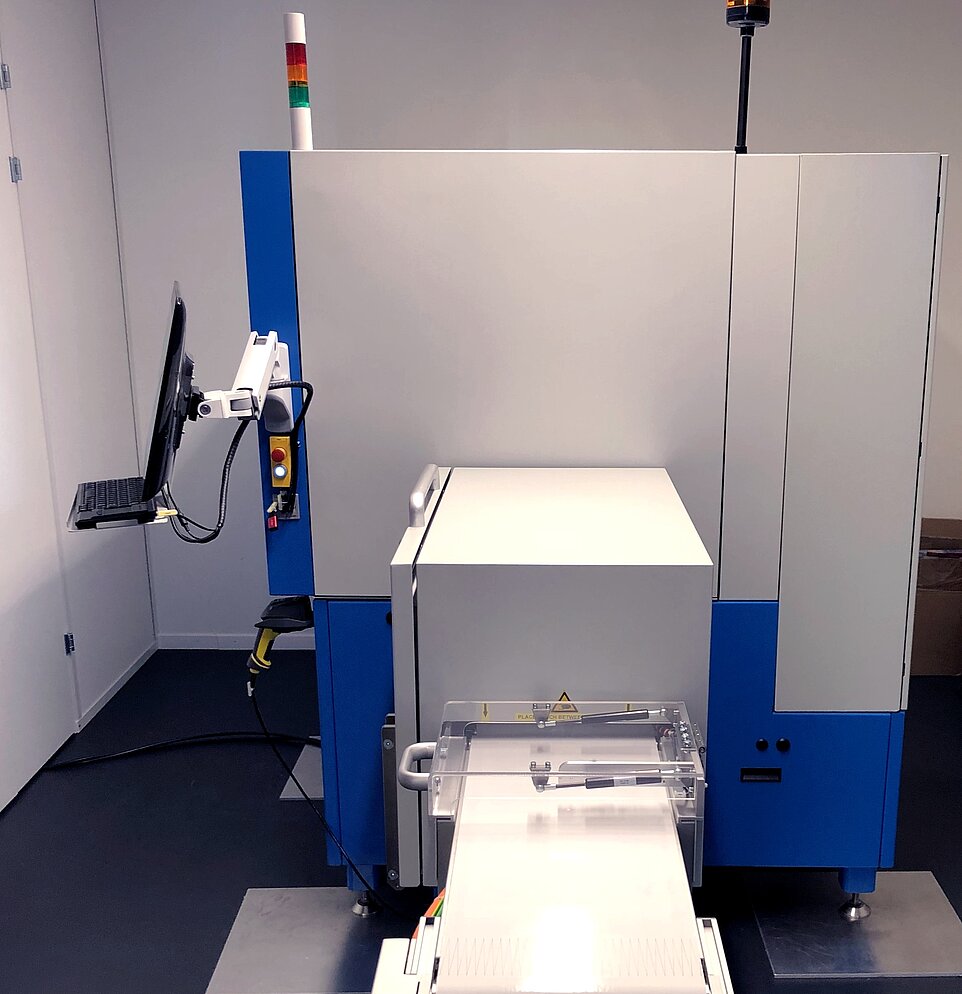

This specific variant of our autonomous inspection systems is used for manufactured parts which are automatically supplied by a conveyor belt. We call this variant an "In-Line" System.

On the running mode, there is absolutely no need for any human intervention, as far as the parts are correctly supplied in the production process. The system independently scans all nest positions, identifies, measures and inspects the parts, and issues test reports. Moreover, the system can easily and quickly be adapted to new products with similar specifications. Test runs once learnt will simply be reloaded.

Customer benefits

This complete solution is particularly suitable for parts manufacturers that experience increasing batch volumes.

The cell is specifically designed to adapt to customer-specific requirements with respect to inspection type, layout, and the ability to manage large parts varieties. A demand-oriented solution which is not only budget-friendly, but also innovative!

The Use of X-Ray Technology

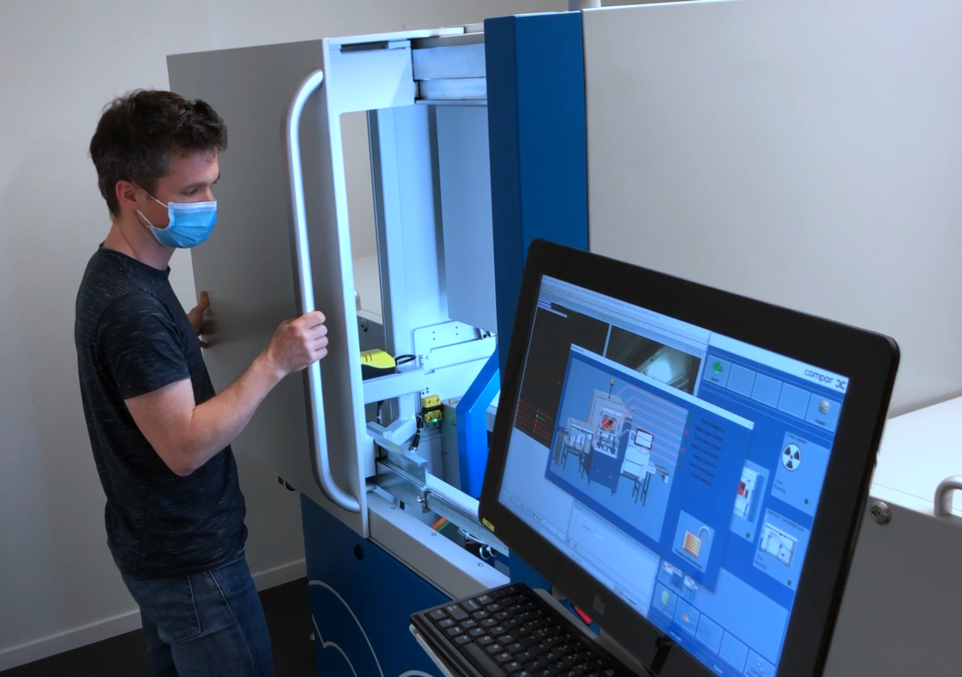

Compar AG uses the latest technology, also known as "direct conversion - photon counting technology", to build complete X-RAY systems, with the advantage that a very high image resolution can be achieved with a low radiation dose.

Even the smallest differences can be made visible and detected! With the great help of our own image processing software, VISIONexpert®, the machine is totally autonomous in order to perform a comprehensive inspection. Compar AG has successfully passed all required certifications to build such X-Ray systems. Every single X-Ray Compar machine is unique, because it's specifically adapted to the customer's requirements.

Modular Standard Concept

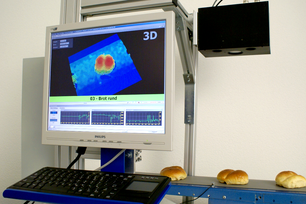

The main features of X-RAY inspection are seal integrity and completeness, end-of-line inspection of packaging and dimensional inspection of inlay metal structures on plastic parts (Medtech proofed).

The Compar X-RAY system is characterized by its ability to cover a wide range of parts, from small to large parts. Of course, the Compar X-RAY system complies with all necessary guidelines and meets all relevant standard norms. In addition, the X-Ray system can be quickly and cost-efficiently equipped with further modules due to the modular concept. Also available as an offline laboratory system. Finally, the system is characterized by high availability and is extremely low-maintenance.