Zero Teaching. Maximum Precision.

Zero Teaching. Maximum Precision.

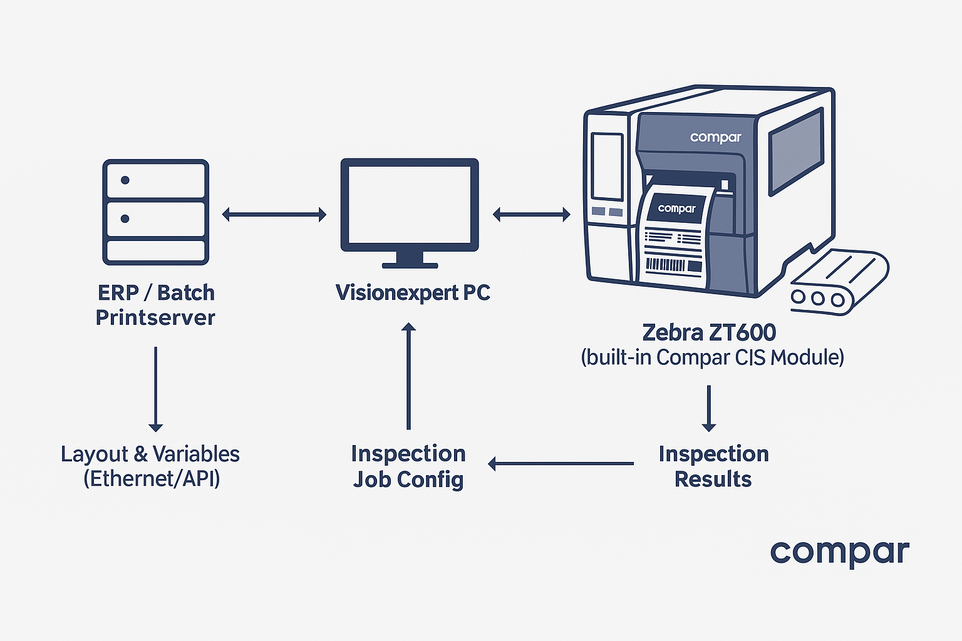

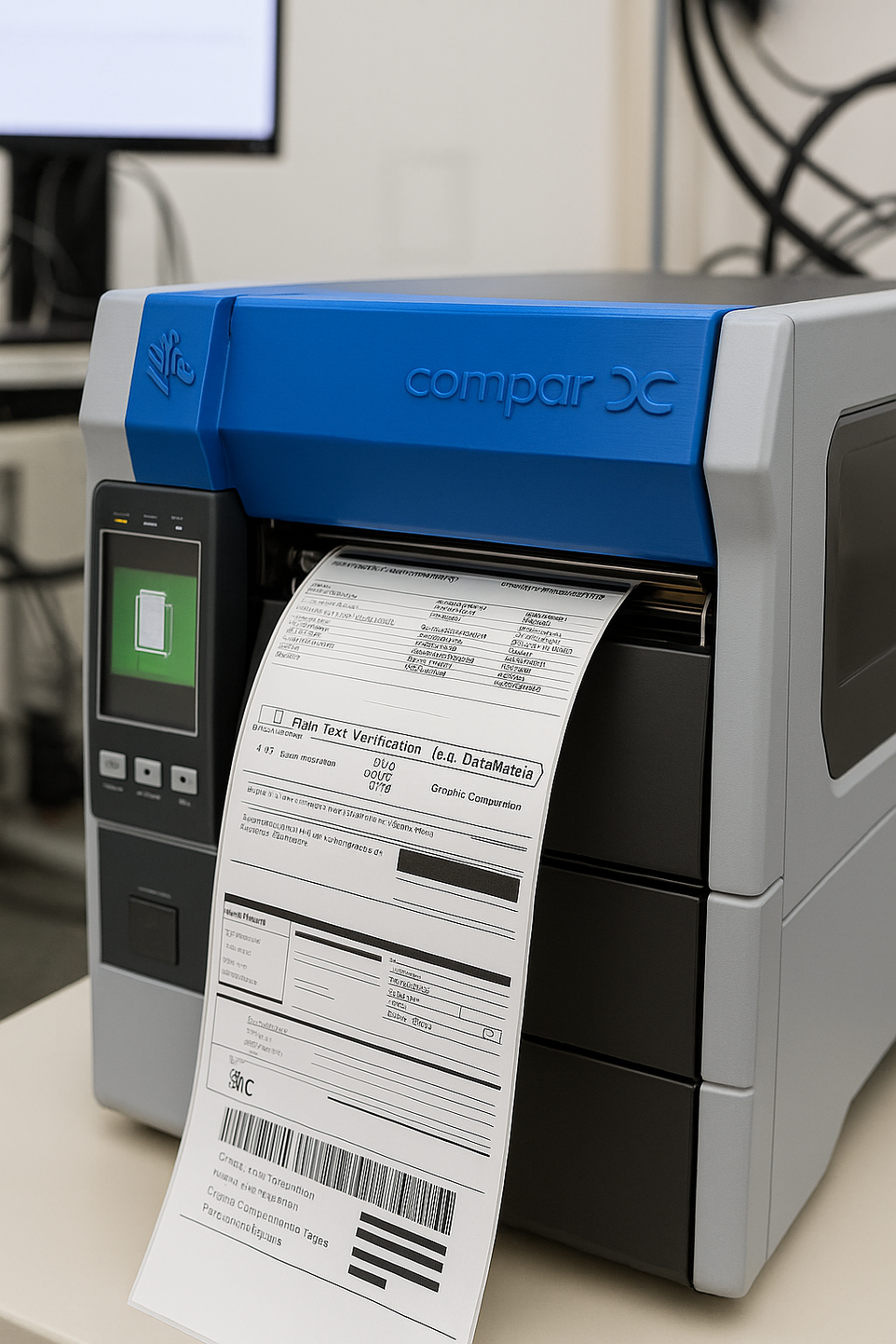

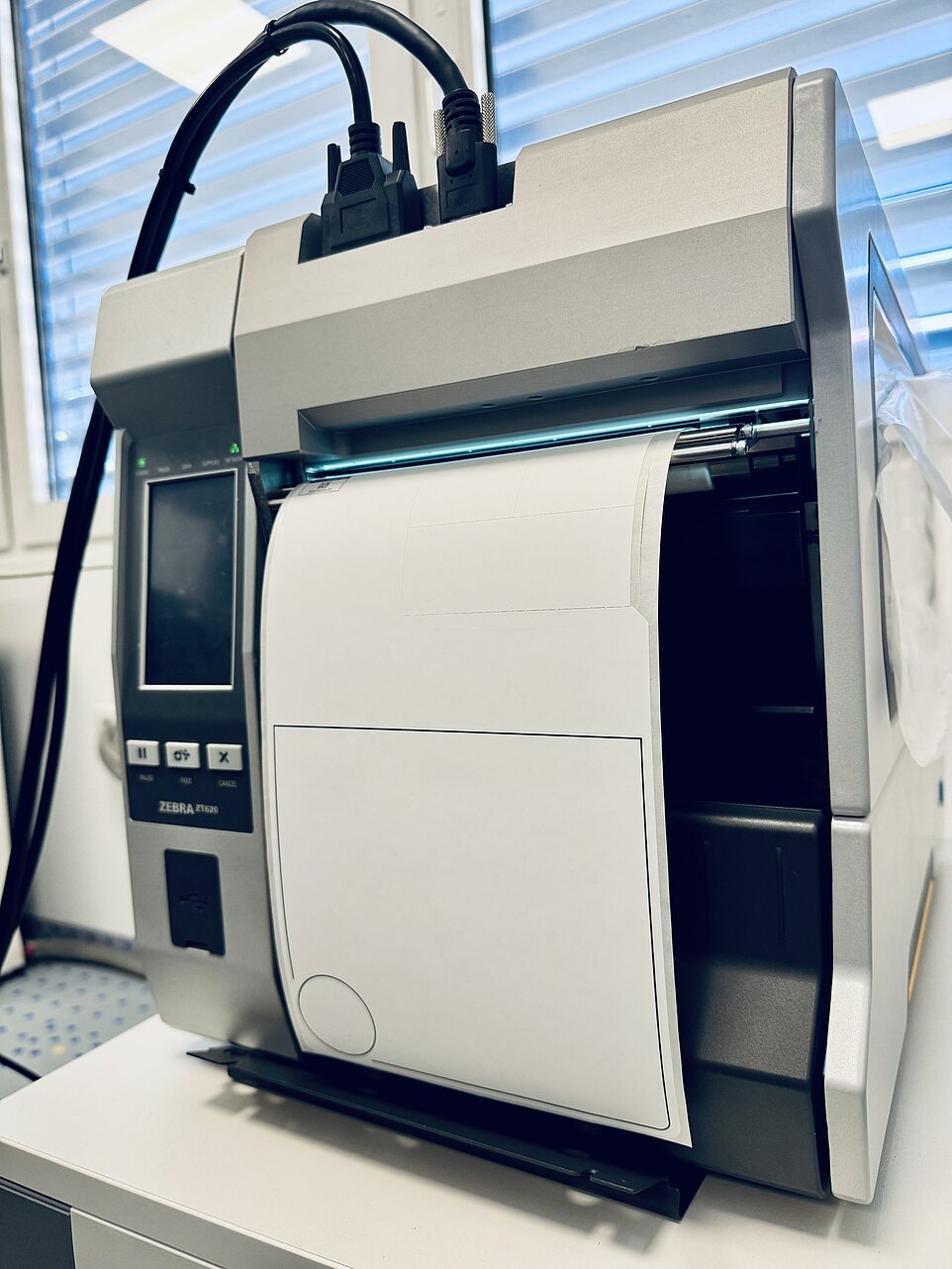

The Compar label quality inspection solution for the Zebra ZT600 series ensures seamless integration, high-precision up to 1200 dpi inspection, automated ERP data management, and enhanced security through defect marking - and uniquely eliminates the need for any teaching or training runs. It uses layout files such as PDF, image, or ZPL as direct reference. This makes label quality control more efficient, reliable, and truly plug-and-inspect.

Core Capabilities

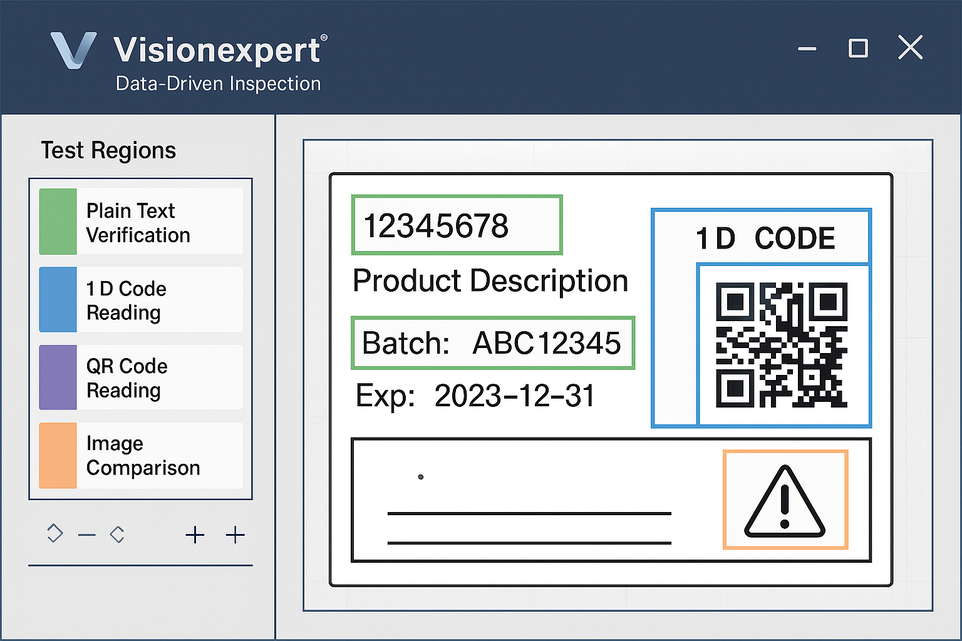

OCR & Plain Text Verification – Text validated against original data.

1D/2D Code Inspection – Reliable reading of barcodes, QR, and DataMatrix.

Graphic & Layout Comparison – Detection of deviations in logos and symbols.

Automated Region Mapping – Direct extraction of test zones from layout files.

Dynamic Field Detection – Identification of variable ERP/ZPL data fields.

Advanced Diagnostics (AD) – Full error traceability and audit trail.

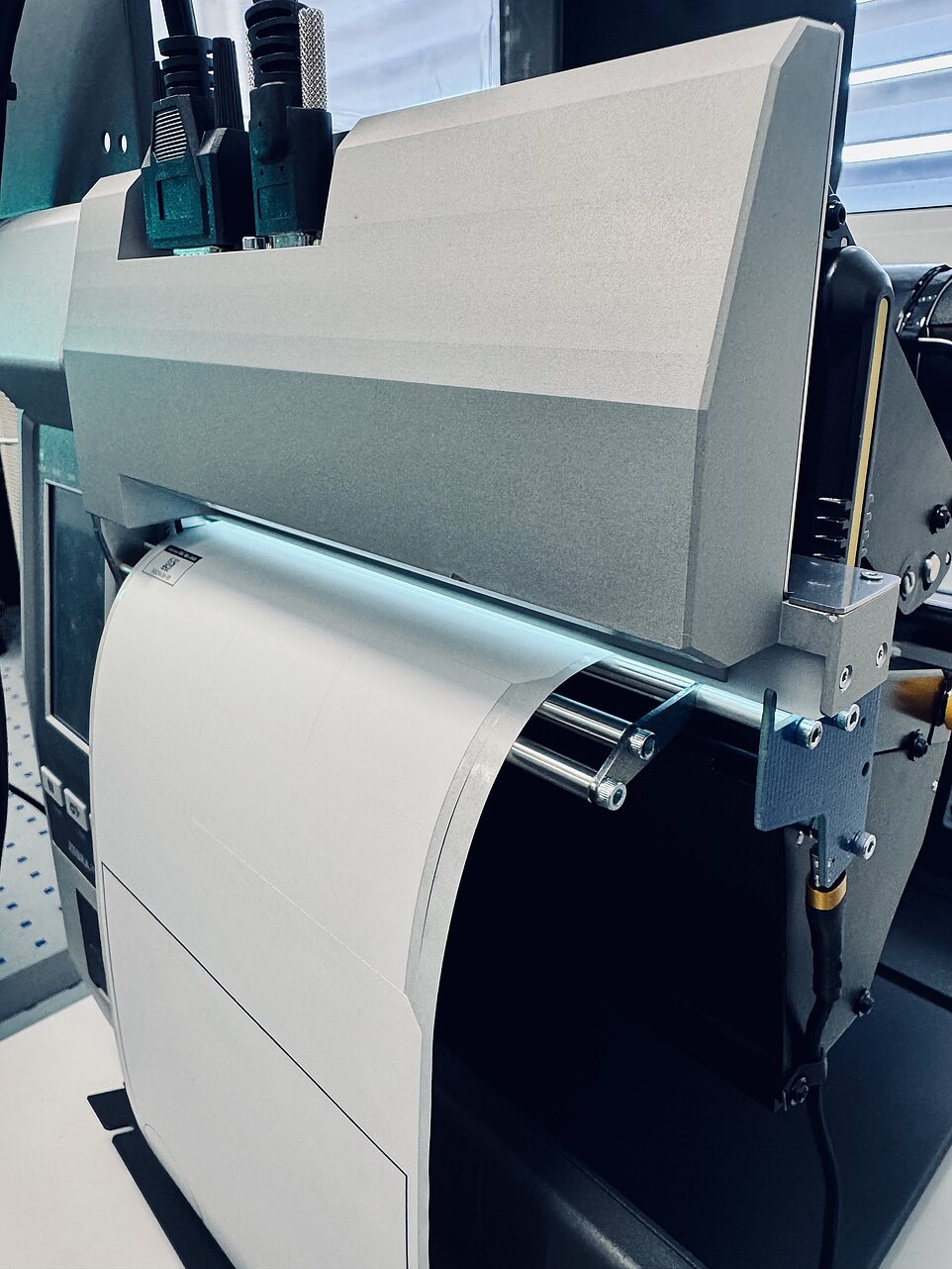

Hardware Module – CIS Integration

Scan width: 8–8.5” (up to 216 mm)

Resolution: 600 dpi monochrome

Integrated lighting: White, optional IR

Depth of field: 0.1 mm

Scanspeed: 32.7 µs/line at 600 dpi

Signal processing: CIS → CameraLink conversion

Incremental encoder: Magnetic, precise synchronization with print speed

Software – Visionexpert®

Modular licenses: OCR, 1D/2D, Image Comparison

Jobfile-based region assignment

Real-time validation against printer data

ERP interface for automated print approval & triggering

Audit-ready with compliance to 21 CFR Part 11 & GAMP5

System Integration

ERP & Batch Print Server connectivity for automated label approval

Vision-PC as communication hub (CameraLink, GigE, USB3 Vision, 2x GbE, RS-232/485)

Inline & Offline operation (100% real-time inspection or sample testing)

Optional overprint of defective labels to block further processing

Benefits at a Glance

✅ No teaching – reference-based inspection

✅ 600 dpi quality control – above printer resolution

✅ ERP-integrated workflow & full traceability

✅ Inline & offline usability

✅ Full audit trail, 21 CFR Part 11 & GAMP5 compliance

✅ Secure defect marking to prevent mix-ups